DMAIC

Successfully implementing Six SigmaDMAIC stands for Define, Measure, Analyse, Improve and Control. It refers to a data-driven improvement cycle used to improve, optimise and stabilise business processes. The DMAIC improvement cycle is the essence used to drive Six Sigma-projects and achieve the desired outcome.

Almost every organisation has improvement projects. Unfortunately, in 80% of the cases, organizations fail to successfully implement the desired changes .

This is often due to resistance from the workers or unclear agreements between vision and strategy.

To be among that 20% of successful change-agents, it is important to know clearly what the problem is and how it translates into quantitative data. That’s very important in the final translation of the customer requirement into business processes.

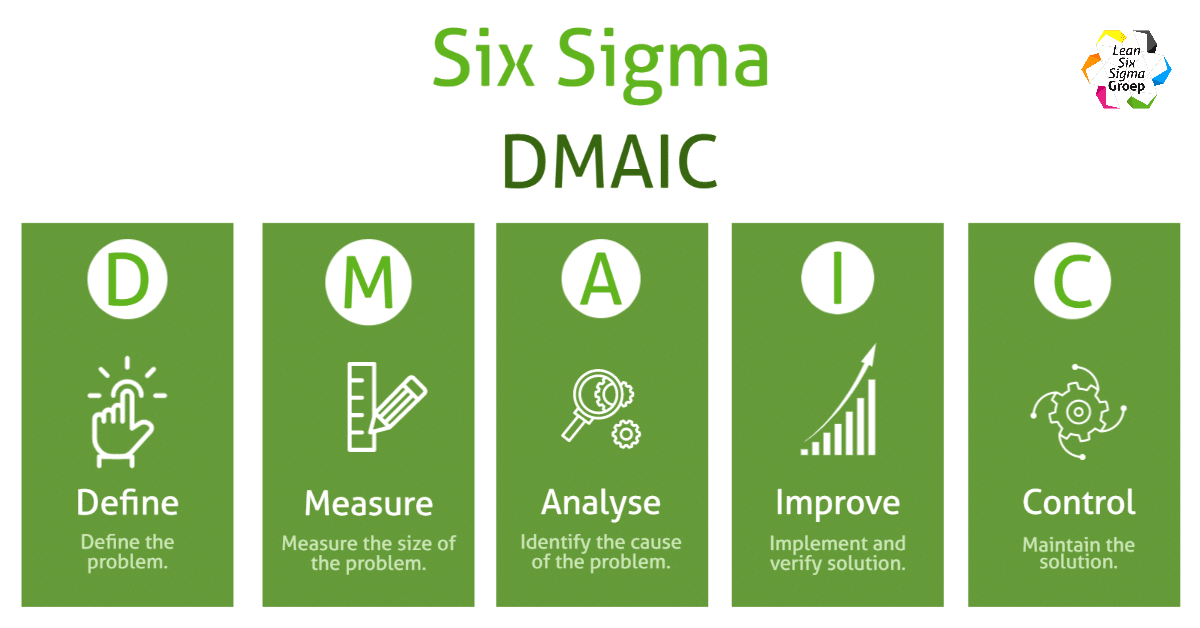

5 steps within DMAIC

The basis from which Six Sigma works is the DMAIC-model. This consists of the following five steps:

- Define: In the Define-phase, we define the problem by answering the following questions:

- Who is the customer?

- What is important to them?

- What process is involved?

- How do we capture the outcomes?

- Measure: In the Measure-phase, relevant data are measured and collected.

The process will be mapped out. In addition, we implement a measurement system analysis and determine the size of the problem. - Analysis: In the Analysis-phase, we analyse the collected data.

Here we determine the influencers of the problem, conduct a data and process analysis and identify the biggest (root-)causes. One of the seven basic quality analysis tools is the Ishikawa-diagram. - Improve: In the Improve-phase, improvements are conceived, tested and implemented. This involves finding solutions to the biggest causes, selecting the best solutions and then implementing them.

- Control: The Control-phase is about sustaining and managing the improved process. Securing the implemented solution is important here, for example by setting up a permanent measurement that tracks process performance.

DMAIC in Lean Six Sigma

Today, the DMAIC-cycle has evolved in such a way that it is much more widely applicable to improvement projects. The DMAIC-model is used in the Lean Six Sigma-methodology, in combination with Lean- principles. Read more about the combination of Lean and Six Sigma here.

The distinctive aspect of Lean Six Sigma Groep lies in its incorporation of the DMAIC model along with other methodologies to ensure comprehensive improvement. By integrating these approaches, factors such as workplace culture and resistance are given due consideration and are not disregarded.

Within our Lean Six Sigma Green Belt and Lean Six Sigma Black Belt-training courses, the methods are covered in a practice focused manner.