The transition from Green Belt to Black Belt

Would you like to learn how to guide and implement the improvement projects but already successfully completed the Green Belt training? Then the Lean Six Sigma Green Belt to Black Belt training will be the right choice for you.

With our Green to Black Belt programme, both your statistical knowledge and your Lean Agile Six Sigma techniques are expanded and deepened within 8–10 days. You will also learn how to coach Green Belts within your organisation and how to support them with statistics.

In broad terms, the programme consists of the following:

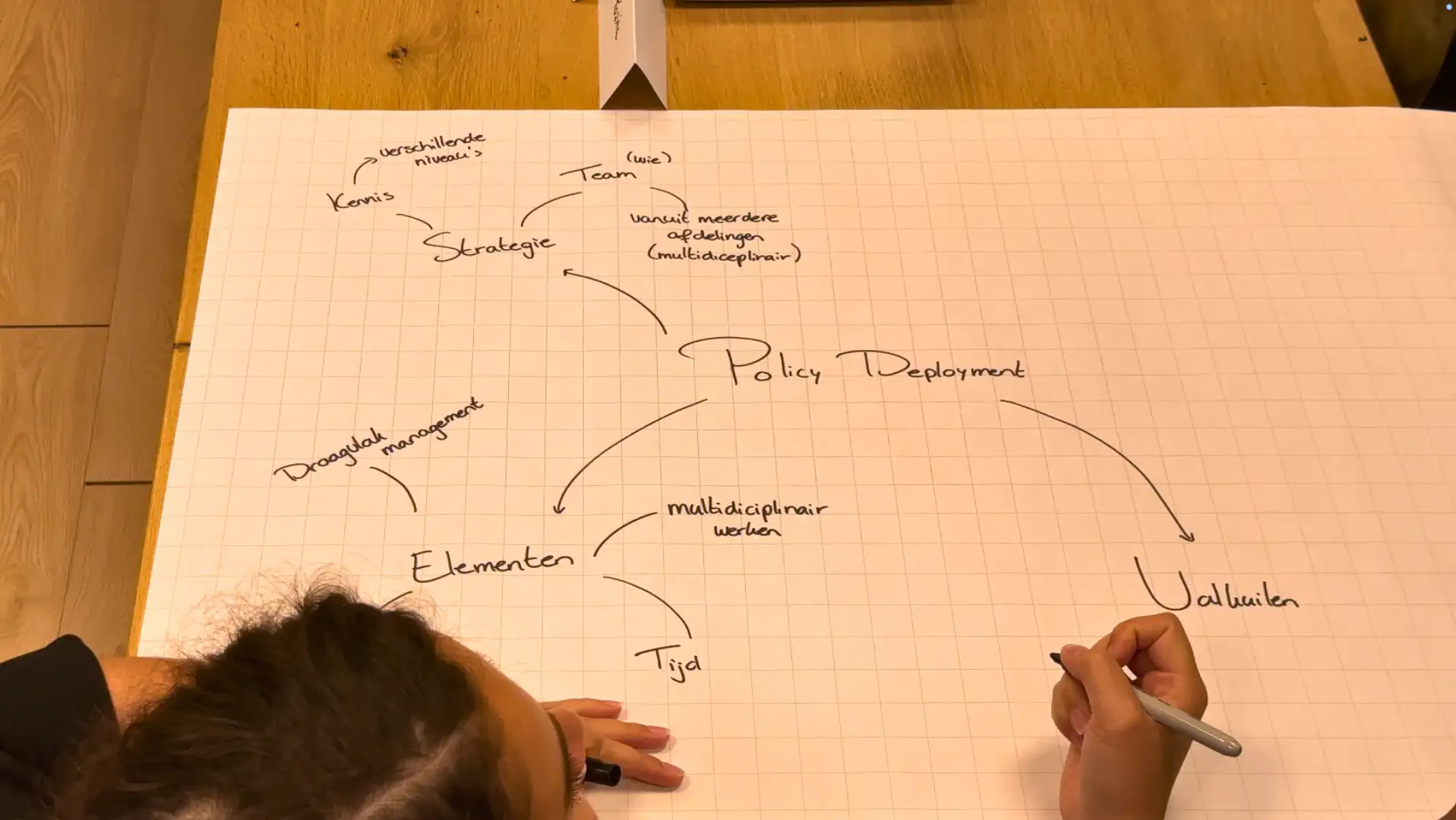

Policy Deployment, 2 days

Masterclass Policy Deployment and Operational Management: This advanced module focuses on the question, “How do we roll out process improvement across an organisation, and what does that require?” Step by step, you will design an improvement programme for your own organisation. Techniques such as Scrum, Lean Leadership, OGSM, and the Change Map are covered.

Advanced Six Sigma, 2 days

Part of the Lean Six Sigma curriculum

Masterclass Advanced Six Sigma: In this module, participants learn to analyse data using the Six Sigma method. Topics include hypothesis testing, process performance analysis, and measurement system analysis. No abstract statistics—just practical examples and real application.

The total duration of the Green Belt to Black Belt programme is 8–10 days, divided across multiple modules over the course of several months. Training hours are from 09:00 – 17:00.

Between the modules, you will work on assignments that allow you to apply the theory directly in your own work environment. Expect to spend approximately 1 to 2 half-days on this, depending on your experience and the complexity of your improvement project.

After completing the training, you can take the Black Belt theory exam. Preparation time varies per participant, but on average, around 12 hours of study is needed to successfully pass the exam.

During the programme, you will work toward coaching and guiding Green Belts within your organisation. To help you practise this effectively, we support you with two personal coaching sessions led by an experienced Master Black Belt.

During these sessions, we discuss your improvement projects, data analyses, and any questions you may have about guiding others. Coaching takes place via Teams, phone, email, or, if possible, on location.

Would you also like to become practically certified as a Black Belt? In that case, we will guide you in carrying out and completing your practical assignment, enabling you to demonstrate that you can independently lead complex improvement programmes.

Lean Six Sigma Groep is accredited by LCS, IASSC, CRKBO, NRTO, and CEDEO. This means we meet internationally recognised standards and requirements, guaranteeing the quality of our training programmes. After completing this training, you will receive a Black Belt certificate.

Upon completion of the programme, you will receive an LCS Lean Six Sigma Groep certificate of participation. In addition, it is also possible to become fully certified in practice as a Black Belt. The following requirements apply:

After completing the programme, you will be able to lead organisation-wide improvement initiatives and translate complex challenges into measurable results. You will combine Lean, Six Sigma, and Agile techniques at a strategic level and ensure improvements are sustained.

As a Black Belt, you can:

– Design and lead strategic improvement programmes

– Perform advanced data analyses, including hypothesis testing and process performance analysis

– Understand and optimise complex processes using techniques such as Value Stream Mapping

– Combine Lean and Agile to help teams achieve results more quickly

– Coach and guide Green Belts in their projects

– Implement changes sustainably and create organisational buy-in

Receive detailed information

Choose your start date & location

Master Black Belt Consultant

Questions? Contact us