Obeya

What is Obeya and what can you do with it?Obeya is a Japanese term that translates to “large room.” The Obeya methodology originated in the 1990s at Toyota during the development of the Prius. Mr. Uchiyamadade conceived the idea that it would be efficient and effective to create a space where the team could quickly make informed decisions about the approach and development of the new car.

The approach proved to be very effective. All information was visibly present in the room, aiding the team in steering development and making on-the-spot decisions. Due to this “visibility,” an Obeya is also referred to as a Visual Management Room (VMR).

Obeya and Lean Agile

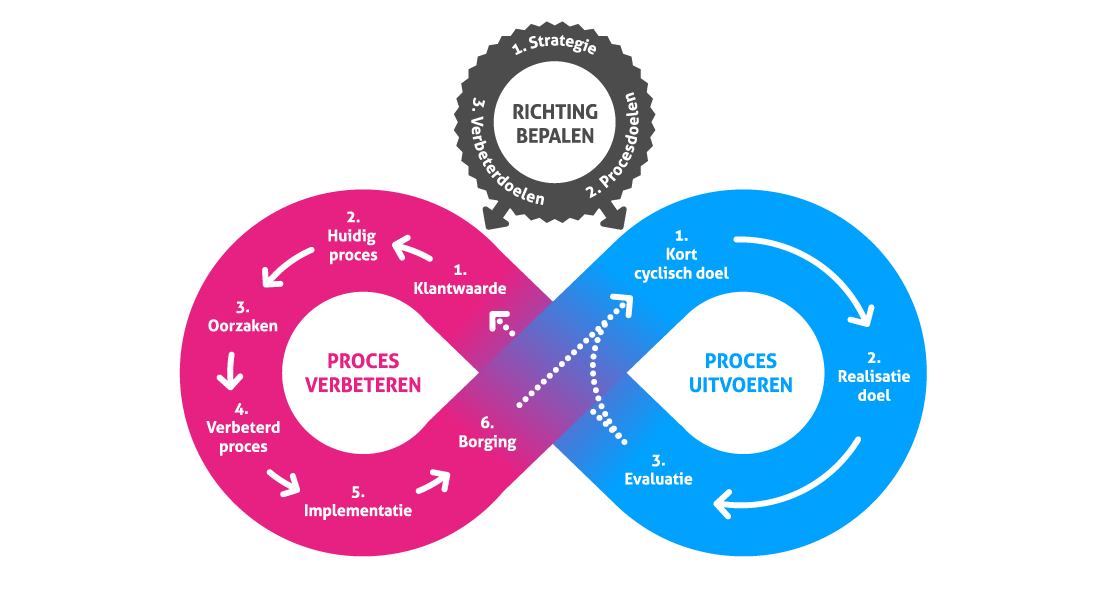

The Obeya principle is now widely used in various contexts. We often apply the method in steering organizations and departments. Our Lean Agile vision, which connects determining direction, improvement, and execution, aligns well with Obeya.

The elements from the vision can be effectively materialized in an Obeya space. Thus, it becomes a powerful tool to combine the realization of your strategic improvements with the monitoring of your operational performance. Together, this leads to the best results for customers, employees, and the organization.

In an Obeya space, we create a strategy wall, a change wall, and a process wall. We begin with setting up the strategy and translate it into improvement projects and process KPIs essential for realizing the strategy.

We accompany this with an Obeya dialogue with the management team of the respective department. This way, an annual plan comes to life, and tangible steps are taken.

Getting Started with Obeya

The foundation of the methodology is, like many techniques from Lean and Agile, relatively straightforward and practical. The challenge lies in effectively and result-oriented application. Finding a space, filling it with charts and diagrams, and conducting a conversation is manageable, even in the increasingly common and necessary digital variants.

However, a well-functioning Obeya demands much more from a department or organization: preparation, discipline, the right dialogue and behavior, and, of course, relevant information. Lean Six Sigma Groep has an implementation approach that addresses all these elements.

Consequently, you not only get a set-up Obeya but also a functional structure that provides management insight and control over the organization, leading to concrete performance improvement.

This also requires a commitment from management and the organization. An Obeya standup, as we establish it with the client, leads to a ‘Pull’ towards the rest of the organization.

The Obeya needs to be fed with relevant and current information from that organization. Hence, the implementation of a good Obeya has a much broader impact than just the space and the conversation itself. Concrete contributions and input are requested from the ‘underlying’ layers.

The Obeya guides these layers, monitors how successfully they follow the direction, and initiates help where needed. Through this ‘Pull,’ a cascade of Obeyas can also be created or realized. Here, one Obeya feeds the one above it.

Results of Implementations

In addition to this ‘indirect’ impact on the organization, we observe the following direct results in Obeya implementations:

- Improved insight and a better dialogue overall lead to better, well-balanced, and supported decisions.

- A better balance between daily operations and improvement projects is achieved, and tangible steps are taken to implement the strategy.

- Planned improvements are actually realized, or if not successful, there is a clear basis for why and a prompt decision to proceed or not.

- The structure and stand-ups lead to an active posture in (usually somewhat dull) management meetings.

- As a result, there is better understanding of each other’s situations, fostering improved collaboration.

All change is challenging, and clear insights and sharp dialogues can be confronting at times. Nevertheless, we also see a lot of joy in a well-functioning Obeya, and as Lean Agile Groep, we are happy to contribute to that, even in your organization! For more information or a tailored proposal, please contact us via email or by phone at 088-5326700.