DMAIC

Explore DMAIC, a key methodology in Lean Six Sigma, for effective problem-solving and process improvement, encompassing Define, Measure, Analyze, Improve, and Control.

Almost every organisation has improvement projects. Unfortunately, in 80% of the cases, organizations fail to successfully implement the desired changes .

This is often due to resistance from the workers or unclear agreements between vision and strategy.

To be among that 20% of successful change-agents, it is important to know clearly what the problem is and how it translates into quantitative data. That’s very important in the final translation of the customer requirement into business processes.

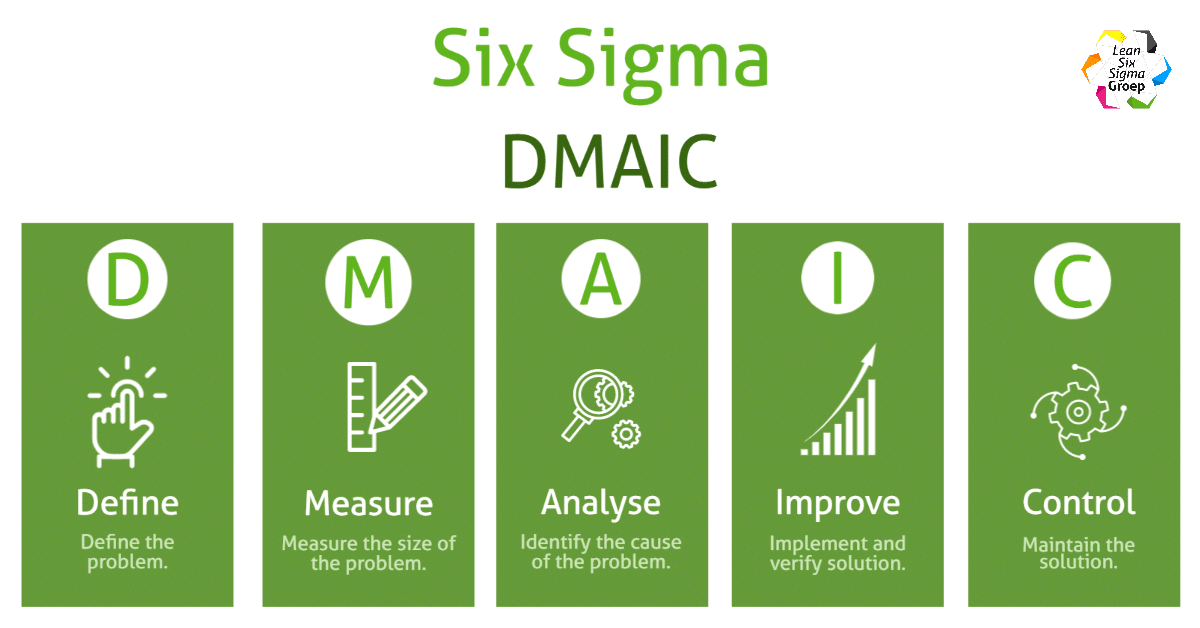

5 steps within DMAIC

The basis from which Six Sigma works is the DMAIC-model. This consists of the following five steps:

- Define: In the Define-phase, we define the problem by answering the following questions:

- Who is the customer?

- What is important to them?

- What process is involved?

- How do we capture the outcomes?

- Measure: In the Measure-phase, relevant data are measured and collected.

The process will be mapped out. In addition, we implement a measurement system analysis and determine the size of the problem. - Analysis: In the Analysis-phase, we analyse the collected data.

Here we determine the influencers of the problem, conduct a data and process analysis and identify the biggest (root-)causes. One of the seven basic quality analysis tools is the Ishikawa-diagram. - Improve: In the Improve-phase, improvements are conceived, tested and implemented. This involves finding solutions to the biggest causes, selecting the best solutions and then implementing them.

- Control: The Control-phase is about sustaining and managing the improved process. Securing the implemented solution is important here, for example by setting up a permanent measurement that tracks process performance.