Deze site maakt gebruik van cookies, zodat wij je de best mogelijke gebruikerservaring kunnen bieden. Cookie-informatie wordt opgeslagen in je browser en voert functies uit zoals het herkennen wanneer je terugkeert naar onze site en helpt ons team om te begrijpen welke delen van de site je het meest interessant en nuttig vindt.

Wat is een Value Stream Map?

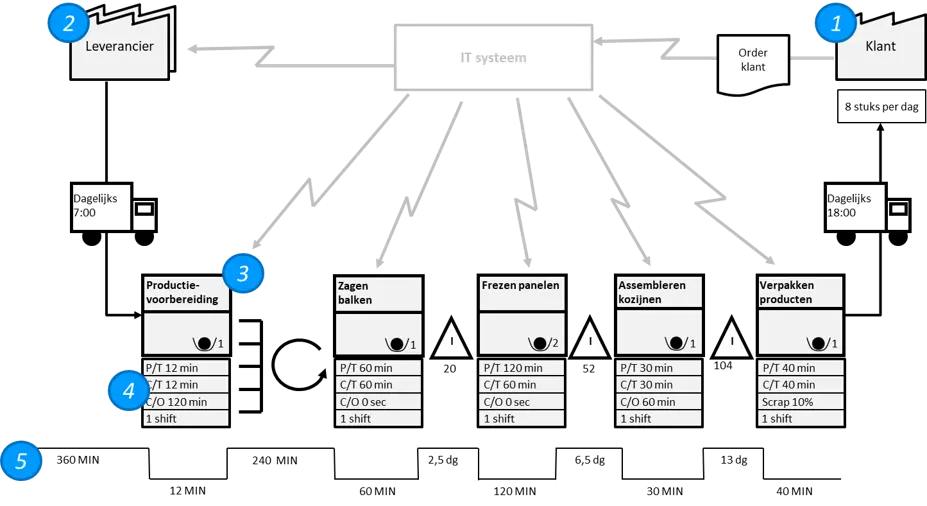

Een Value Stream Map is een datarijke procesmap. De productstroom, de procesflow, wordt zichtbaar gemaakt en aangevuld met data en andere relevante informatie. De VSM geeft een overzicht hoe een product door het proces naar de klant stroomt, het geeft inzicht in de verspillingen en in overbodige processtappen.

Betekenis

De vertaling ‘waardestroom’ kan misleidend zijn. De VSM bevat namelijk álle processtappen, ook die waarvan later blijkt dat deze stap geen waarde toevoegt aan het product.

Kenmerken van de VSM

- Een VSM wordt van RECHTS naar LINKS opgesteld. Te beginnen bij de klant; bij het eindproduct dat de klant ontvangt.

- Een VSM wordt altijd opgesteld met de medewerkers die in het proces werkzaam zijn.

- Een VSM wordt vaak op bruin papier (van een rol) gemaakt. Alle informatie wordt op post-its geschreven en op het vel papier geplakt. Aanpassen van het proces gaat zo op de meest handige manier.

Methode om VSM op te stellen

Allereerst bepaal je welk proces je nader wilt bekijken. Welk proces loopt niet goed en moet verbeterd worden?

Een VSM wordt opgebouwd in een aantal stappen:

- Begin bij de klant. Bepaal wie de klant is en wat hij wil. Hoeveel producten wil de klant ontvangen, wanneer en op welke manier?

- Benoem de belangrijkste leveranciers. Hoe vaak wordt er geleverd, wat wordt er geleverd en op welke wijze?

- Teken de processtappen te beginnen bij de laatste, dit is de klant. Stel steeds de vraag: ‘Van wie kreeg hij/zij dit?’. Omschrijf de processtappen in het kort.

- Verzamel relevante data bij de processtappen in een databox. Bv. processtime, cycletime, hoeveel uitval per processtap.

- Verzamel aanvullende informatie over de flow van het proces, zoals hoeveel voorraad en hoelang ligt dit te wachten, hoelang duurt de processtap.

Het huidige proces is nu in kaart gebracht, dit heet de current state. Dit is de routing die een product volgt, op dit moment. Het is een visuele weergave van het proces inclusief materiaal en informatiestromen. Bronnen van verspilling worden getoond, zoals voorraad, wachttijd.

De plaatsen van verspilling zijn plaatsen waar, na een goede analyse, verbeterd kan worden.

Je brengt vervolgens de ideale VSM in kaart. Een waarbij het product zonder verspilling door het proces stroomt. Dit heet de future state van de VSM.

Nu volgt het opstellen en uitvoeren van een verbeterplan om tot de future state van de VSM te komen.

Voordelen van een Value Stream Map

Alle medewerkers uit het proces hebben hetzelfde overzicht van het proces. Het is een gezamenlijk proces geworden. Met elkaar kan nu de stap naar een verbeterd proces gezet worden.

Voorbeelden van een Value Stream Map